The Importance of Auto & Industrial Friction Services

Friction is a fundamental force that affects all moving parts. In vehicles, friction is harnessed for braking and power transmission. In industrial settings, it’s crucial for everything from conveyor belts to robotics. Proper management of friction is essential for safety, performance, and longevity. Ignoring friction-related issues can lead to catastrophic failures, costly repairs, and downtime.

Brake System Maintenance: The Cornerstone of Auto Friction Services

Brake systems are arguably the most critical safety feature of any vehicle. Regular maintenance, including inspections, pad/shoe replacements, and fluid flushes, is paramount. Modern braking systems incorporate advanced technologies like ABS and electronic stability control, requiring specialized knowledge for proper servicing.

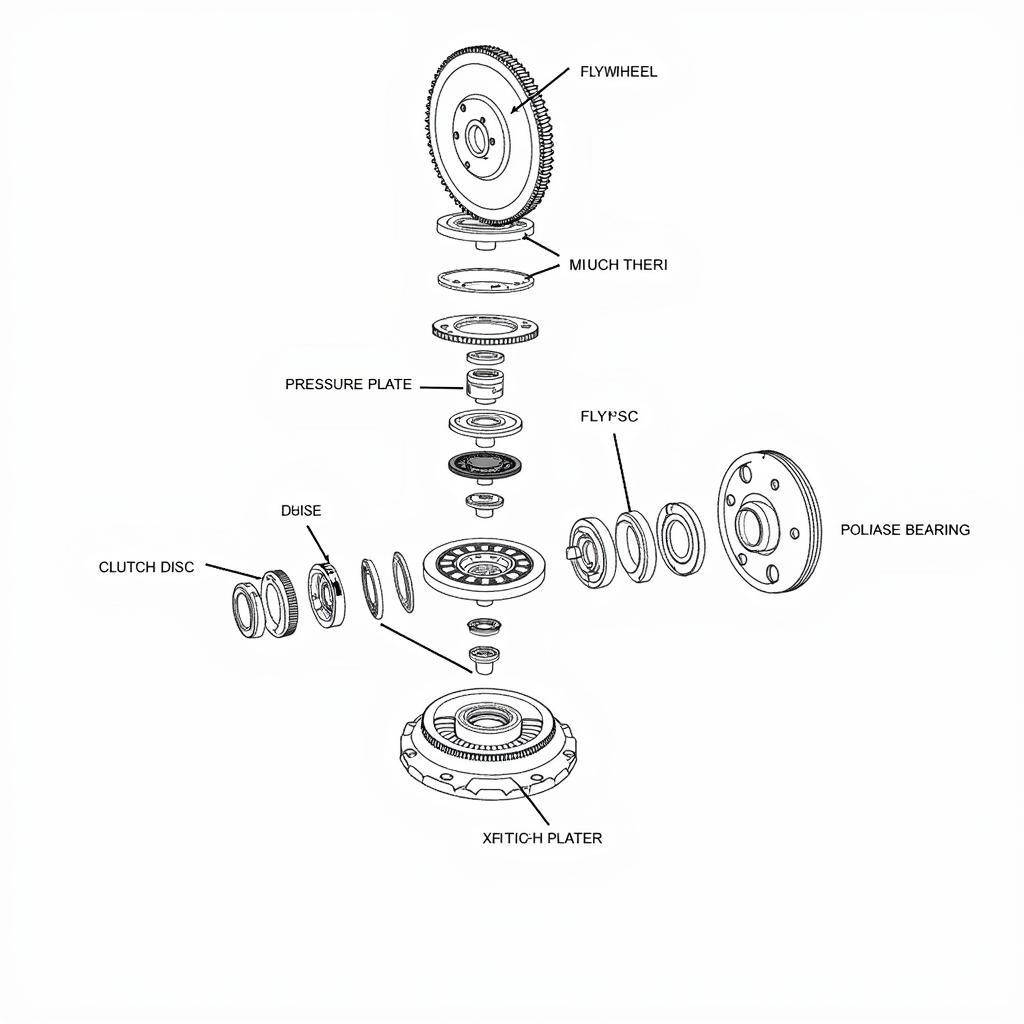

Clutch Systems: Ensuring Smooth Power Transmission

Clutch systems are responsible for transferring power from the engine to the transmission, enabling smooth gear changes. A worn or malfunctioning clutch can lead to jerky starts, difficulty shifting, and reduced fuel efficiency. Proper clutch maintenance includes regular adjustments and timely replacement of worn components.

Clutch System Components and Their Function

Clutch System Components and Their Function

Industrial Friction: A World Beyond Brakes and Clutches

Industrial friction services encompass a broad range of applications beyond automotive. From heavy machinery used in construction and mining to precision robotics in manufacturing, friction management is crucial for optimal performance and safety.

Friction Materials in Industrial Applications

The selection of appropriate friction materials is crucial in industrial settings. Factors like operating temperature, pressure, and environmental conditions influence the choice of materials. Specialized friction materials are designed to withstand extreme conditions, ensuring reliability and longevity.

Predictive Maintenance: Minimizing Downtime and Maximizing Efficiency

Predictive maintenance leverages data analysis and sensor technology to anticipate potential friction-related issues before they lead to failures. This proactive approach minimizes downtime, optimizes maintenance schedules, and reduces overall operating costs.

Choosing the Right Auto & Industrial Friction Service Provider

Selecting a qualified service provider is crucial for ensuring the safety and reliability of your vehicles and equipment. Look for providers with certified technicians, specialized equipment, and a proven track record of excellence.

- Certifications and Expertise: Ensure the service provider employs technicians certified by recognized industry organizations.

- Specialized Equipment: Modern vehicles and industrial machinery require specialized diagnostic and repair equipment.

- Reputation and Reviews: Check online reviews and testimonials to gauge the provider’s reputation and customer satisfaction.

“Choosing the right friction service provider is an investment in safety and performance. Don’t compromise on quality when it comes to the reliability of your equipment.” – John Miller, Chief Engineer, Apex Industries

Conclusion

Auto & industrial friction services are essential for maintaining the safety and efficiency of vehicles and machinery. From routine brake maintenance to complex industrial friction applications, understanding the principles of friction and choosing qualified service providers is crucial. By prioritizing proactive maintenance and staying informed about the latest advancements in friction technology, you can ensure optimal performance, minimize downtime, and enhance safety.

FAQ

- How often should I have my brakes checked?

- What are the signs of a worn clutch?

- What are the different types of industrial friction materials?

- What is the role of lubrication in friction management?

- How can predictive maintenance improve efficiency?

- What certifications should I look for in an auto mechanic specializing in friction services?

- How can I find a reputable industrial friction service provider?

If you need further assistance or have any questions, please contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 321 Birch Drive, Seattle, WA 98101, USA. Our customer service team is available 24/7.