Auto Lift Repair Service is crucial for maintaining the safety and efficiency of any vehicle repair shop. A malfunctioning lift can lead to serious accidents, downtime, and ultimately, a hit to your bottom line. This comprehensive guide dives deep into the world of auto lift repair, covering everything from preventative maintenance to troubleshooting common issues. Let’s ensure your lifts are always operating at peak performance. After the introduction, we will discuss finding an apprenticeship as an auto service technician. For those interested in learning about auto service technician apprenticeships, more information can be found on our auto service technician apprenticeship page.

Understanding the Importance of Auto Lift Repair Service

Regular auto lift repair service is an investment that pays off in the long run. Think of it like regular oil changes for your car – a small upfront cost prevents major problems down the line. A well-maintained lift not only ensures the safety of your technicians but also improves productivity by minimizing downtime and maximizing efficiency.

Preventative Maintenance: The Key to Longevity

Preventative maintenance is the cornerstone of any successful auto lift repair program. This involves regular inspections, lubrication, and adjustments to keep your lifts in top condition. A proactive approach can identify potential problems early on, preventing costly repairs and extended downtime.

- Regular Inspections: Schedule routine inspections by qualified technicians to identify wear and tear, loose parts, or any other potential issues.

- Lubrication: Proper lubrication is essential for the smooth operation of your lifts. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- Adjustments: Regular adjustments ensure that your lifts are operating within their specified parameters, preventing premature wear and tear.

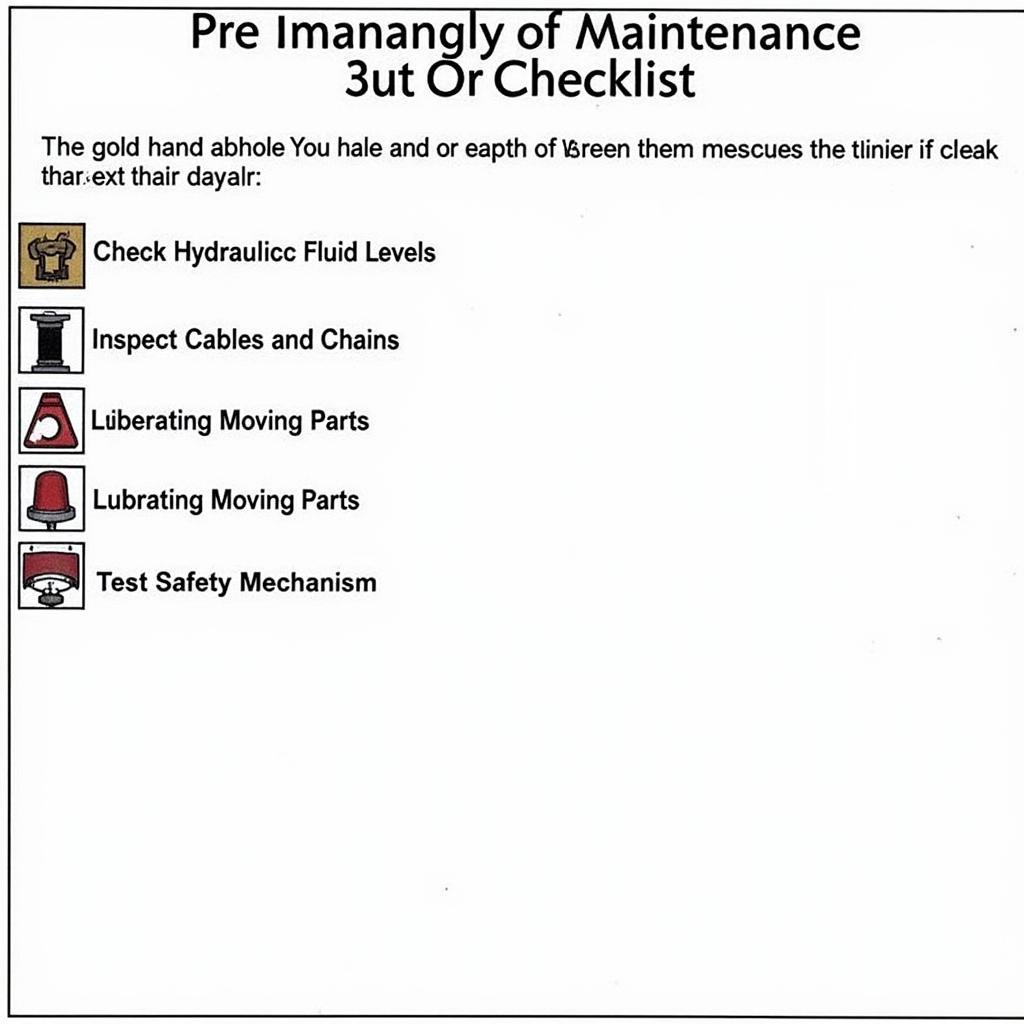

Auto Lift Preventative Maintenance Checklist

Auto Lift Preventative Maintenance Checklist

Troubleshooting Common Auto Lift Issues

Despite regular maintenance, issues can still arise. Knowing how to troubleshoot common problems can help you minimize downtime and get your lifts back in operation quickly.

- Hydraulic Leaks: Check for leaks in hoses, cylinders, and fittings. Repair or replace any damaged components.

- Uneven Lifting: This can be caused by worn-out cables, uneven wear on the lift arms, or problems with the hydraulic system.

- Slow Operation: Low hydraulic fluid levels, worn-out pumps, or clogged filters can contribute to slow lift operation.

Choosing the Right Auto Lift Repair Service Provider

Selecting a reputable auto lift repair service provider is crucial. Look for a company with experienced technicians, a proven track record, and a commitment to customer satisfaction. Be sure to compare quotes and services, especially if you’re considering services like auto self service. Ask for references and check online reviews before making a decision. A qualified technician can even assist with finding the right auto service with large lift.

“Finding a reliable auto lift repair service provider is like finding a trusted mechanic for your car. You want someone with experience and a solid reputation,” says John Davis, Senior Automotive Technician at Apex Auto Repair.

Investing in Regular Auto Lift Repair: A Smart Business Decision

Regular auto lift repair service is not just a safety requirement; it’s a smart business decision. By minimizing downtime, maximizing productivity, and extending the lifespan of your equipment, you’re protecting your investment and ensuring the success of your business.

“Preventative maintenance is always cheaper than emergency repairs,” adds Maria Sanchez, Certified Auto Lift Inspector at Lift Solutions Inc. “A little bit of proactive care can save you a lot of money and headaches in the long run.”

Conclusion

Auto lift repair service is a critical aspect of running a safe and efficient auto repair shop. By prioritizing preventative maintenance and addressing issues promptly, you can protect your investment, ensure the safety of your technicians, and keep your business running smoothly. Don’t wait for a problem to arise – invest in regular auto lift repair service today. For specific services like those involving ally servicing auto, it’s important to choose a provider with the right expertise.

FAQ

- How often should I schedule preventative maintenance for my auto lift?

- What are the most common signs of a malfunctioning auto lift?

- How can I find a qualified auto lift repair service provider?

- What are the typical costs associated with auto lift repair?

- How can I minimize downtime during auto lift repairs?

- Are there any specific safety precautions to follow during auto lift operation?

- What type of training and certification do auto lift repair technicians require?

Common Auto Lift Repair Scenarios

- Scenario 1: A technician notices the lift is lowering slowly. What are the potential causes? Low hydraulic fluid, a worn-out pump, or a clogged filter could be contributing to the slow operation.

- Scenario 2: The lift makes a grinding noise when operating. This might indicate a problem with the cables, chains, or other moving parts that require lubrication or replacement.

- Scenario 3: One side of the lift is higher than the other. This often suggests uneven wear on the lift arms or problems with the hydraulic system, requiring professional auto body shops specializing in service truck utility box repairs.

Further Reading and Resources

Explore our other articles related to auto service and maintenance.

For any assistance regarding car diagnostics, auto lift repair, or other auto service inquiries, please contact us through WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 321 Birch Drive, Seattle, WA 98101, USA. We offer 24/7 customer support to cater to all your needs.