The automotive industry relies heavily on precision and durability, and that’s where die casting shines. When it comes to creating complex auto parts with intricate designs and high strength, die casting is a go-to manufacturing process. But navigating the world of auto parts die casting services and understanding quotes can be complex. This comprehensive guide will equip you with the knowledge to confidently source and evaluate die casting services for your automotive needs.

Understanding Auto Parts Die Casting

Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. This mold, called a die, is created from highly durable steel alloys that can withstand high temperatures and pressures.

Why is die casting popular for auto parts?

- Intricate Designs: Die casting allows for the creation of parts with complex geometries and fine details, critical for many automotive components.

- Dimensional Accuracy: The process ensures tight tolerances, resulting in highly accurate and consistent parts, crucial for automotive assembly.

- Excellent Strength: Die-cast parts possess excellent strength-to-weight ratios, contributing to fuel efficiency in vehicles.

- High-Volume Production: Die casting is ideal for mass production, meeting the demands of the automotive industry efficiently.

Common Auto Parts Made with Die Casting:

- Engine blocks and cylinder heads

- Transmission cases

- Steering components

- Brake components

- Door handles and hinges

- Wheel rims

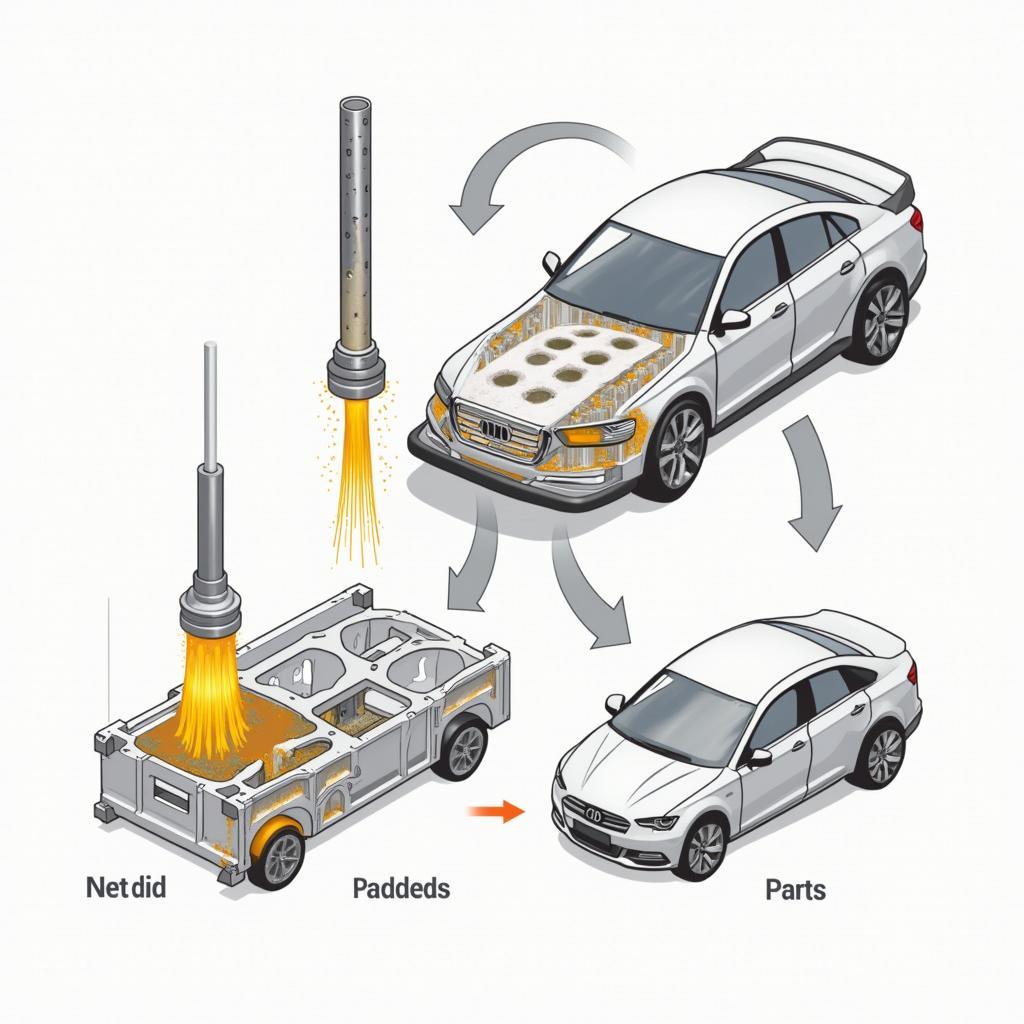

Die Casting Process for Auto Parts

Die Casting Process for Auto Parts

Factors Affecting Auto Parts Die Casting Services Quotes

Several key factors influence the cost of die casting services. Understanding these factors will help you interpret quotes effectively.

- Material Selection: The type of metal (aluminum, zinc, magnesium) significantly impacts cost due to raw material prices and processing requirements.

- Part Complexity: Intricate designs, thin walls, and tight tolerances require more specialized tooling and expertise, affecting the overall price.

- Die Design and Tooling: The complexity and size of the die are major cost drivers. More complex parts necessitate more sophisticated (and expensive) dies.

- Production Volume: Generally, larger production runs result in lower per-unit costs due to economies of scale.

- Finishing Requirements: Post-casting processes like machining, surface treatments, and coatings add to the final cost.

- Geographic Location: Manufacturing costs and labor rates can vary depending on the die casting supplier’s location.

Requesting and Evaluating Auto Parts Die Casting Services Quotes

When seeking die casting services, it’s essential to provide detailed information to receive accurate quotes.

Information to Include in Your Request:

- Detailed Part Drawings: Provide 3D CAD models or 2D drawings with clear dimensions, tolerances, and surface finishes.

- Material Specifications: Specify the desired metal alloy and any required material certifications.

- Production Volume: State your estimated annual or per-order quantity requirements.

- Finishing Requirements: Outline any necessary post-casting processes, such as machining, coatings, or heat treatments.

- Quality Standards: Indicate any required industry standards or certifications.

Evaluating Quotes:

- Beyond Price: Don’t solely focus on the lowest price. Consider the supplier’s experience, capabilities, quality certifications, and lead times.

- Transparency: Look for detailed breakdowns of costs in the quote, including material, tooling, production, and finishing.

- Communication: Choose a supplier who is responsive, communicative, and willing to answer your questions thoroughly.

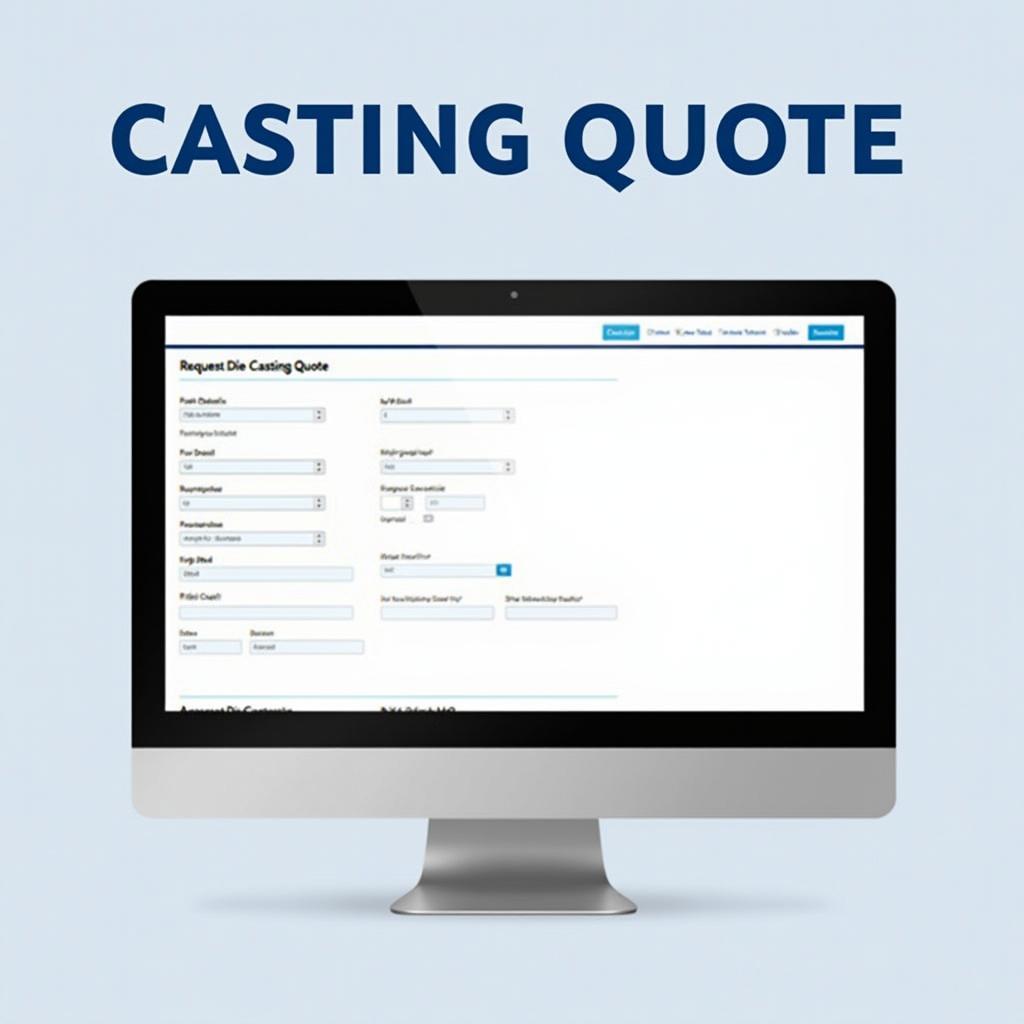

Requesting an Auto Parts Die Casting Quote

Requesting an Auto Parts Die Casting Quote

Benefits of Partnering with a Reputable Die Casting Service

Choosing the right die casting partner offers several advantages:

- Expertise and Experience: Experienced die casters possess the technical knowledge to optimize designs for manufacturability and cost-effectiveness.

- Advanced Technology: Reputable suppliers invest in cutting-edge equipment and technologies to ensure precision, quality, and efficiency.

- Quality Assurance: Dedicated quality control processes and certifications provide peace of mind that your parts meet industry standards.

- Streamlined Production: Partnering with a single source for die casting and finishing simplifies your supply chain and ensures consistent quality.

Finding the Right Auto Parts Die Casting Service for Your Needs

- Industry Networks: Utilize automotive industry associations and online directories to find reputable die casting suppliers.

- Online Research: Conduct thorough online research, exploring company websites, case studies, and customer testimonials.

- Trade Shows and Events: Attending industry trade shows provides valuable opportunities to meet potential suppliers and see their capabilities firsthand.

Conclusion

Securing accurate and competitive Auto Parts Die Casting Services Quotes requires a thorough understanding of the process, influencing factors, and best practices for evaluation. By following the guidelines outlined in this guide, you can confidently navigate the complexities of die casting sourcing and forge a successful partnership with a supplier who meets your specific automotive needs.

Remember, the success of your project hinges not just on finding the lowest price, but on selecting a die casting partner who can deliver the quality, precision, and expertise you deserve.