Cnc Auto Service refers to the use of computer numerical control (CNC) technology in the automotive service and repair industry. While CNC machining itself might not be a common term thrown around your local garage, it represents a significant advancement in how complex car parts are diagnosed, repaired, and even replicated. This article delves into the world of CNC auto service, exploring its benefits, applications, and what it means for the future of car maintenance.

Understanding CNC Machining in an Automotive Context

At its core, CNC machining uses pre-programmed computer software to control machine tools and create parts— in this case, car parts — with high precision. Imagine a robotic arm guided by digital instructions to carve, mill, and shape metal components to exact specifications. This is a simplified way of picturing how CNC technology is integrated into the auto service landscape.

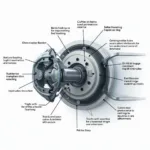

CNC Engine Block

CNC Engine Block

The Advantages of CNC Auto Service

The incorporation of CNC technology brings several advantages to the auto service industry:

- Unmatched Precision: CNC machining eliminates the margin for human error, delivering parts that are manufactured to incredibly precise measurements. This is crucial for engine components, transmission parts, and other intricate systems where even slight deviations can impact performance.

- Faster Turnaround Times: CNC machines work at speeds and efficiencies unmatched by manual labor. This translates to quicker repairs and shorter wait times for car owners.

- Cost-Effectiveness in the Long Run: While the initial investment in CNC technology can be substantial for workshops, the long-term benefits outweigh the costs. The speed and accuracy result in less material waste and fewer faulty parts, ultimately saving money.

Applications of CNC Auto Service

The versatility of CNC machining is evident in its wide range of applications within auto service:

- Engine Rebuilding: From pistons and crankshafts to cylinder heads, CNC machines can create custom-fit components for engine overhauls, ensuring optimal performance and longevity.

- Transmission Repair: The intricate gear systems in modern transmissions require absolute precision. CNC machining allows for the creation of perfectly matched gears and components, leading to smoother shifting and increased lifespan.

- Custom Part Fabrication: For classic car restoration or performance modifications, CNC machining is invaluable. It allows for the creation of unique parts that might no longer be in production or readily available.

CNC Transmission Repair

CNC Transmission Repair

CNC and Diagnostics: A Powerful Partnership

CNC technology goes beyond just creating parts; it plays a crucial role in advanced diagnostics as well.

- Precise Measurement: CNC machines can be used to measure worn-out components with extreme accuracy, providing valuable data for technicians to determine the root cause of problems and recommend the best course of action.

- 3D Scanning and Modeling: Some advanced auto shops utilize 3D scanners in conjunction with CNC machines. This allows for the creation of digital models of damaged parts, which can then be used to manufacture perfect replacements.

CNC Diagnostic Analysis

CNC Diagnostic Analysis

The Future of Auto Service with CNC

As automotive technology continues to evolve, so too will the role of CNC machining in auto service. Here’s what the future might hold:

- Increased Automation: We can expect to see more tasks within the auto repair process becoming automated through CNC technology, further enhancing efficiency and precision.

- Predictive Maintenance: The data gathered through CNC diagnostics can contribute to predictive maintenance models, alerting car owners to potential issues before they escalate into major problems.

Conclusion

CNC auto service is revolutionizing the way we repair and maintain our vehicles. From creating perfectly engineered parts to enabling highly accurate diagnostics, CNC technology empowers mechanics to provide faster, more reliable, and cost-effective services. As we move towards a future of increasingly complex vehicles, the role of CNC in the automotive service industry is only set to grow.